DESIGN ENGINEERING

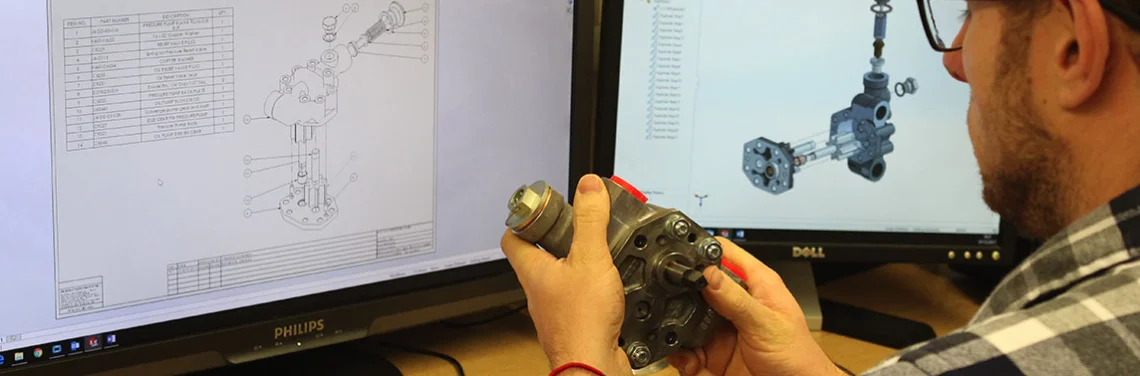

Uniquely in the world of historics, Crosthwaite and Gardiner combines traditional race engineering skills with computer design and modelling capabilities of a calibre usually associated with high end motor industry consulting engineers.

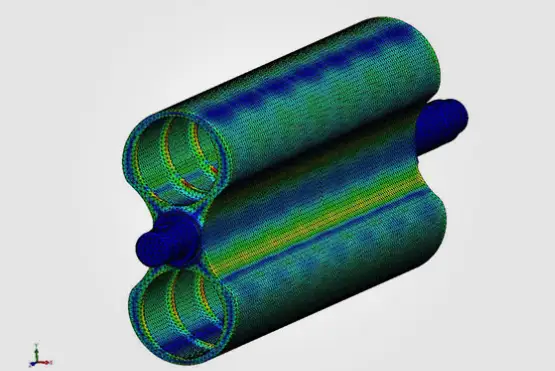

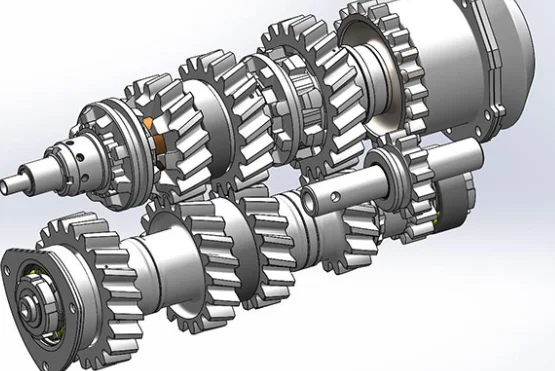

Working closely with leading university research departments and using sophisticated 3D software tools and Finite Element Analysis techniques, our designers accurately model the performance of components in their working environment under a variety of conditions. As well as revealing any potential compatibility problems or failure points to be rectified before manufacture, this allows any number of performance-enhancing virtual modifications to be evaluated.

These theoretical gains are then validated by dynamometer testing a manufactured sample via a multitude of data points, and the results (together with the insights of the engine builder) are fed back into the simulation. This virtuous cycle usually yields substantial performance gains, such as in the design of pistons, porting, cam profiles and any other performance-critical elements.

In conjunction with our large format 3D laser scanner and superbly equipped inspection department, these technologies also allow us to reverse engineer historic components with unprecedented accuracy.

For more information, check out our complete plant list.

FIND OUT MORE